Poplar Works Community Partnership Report

Poplar Works Community Partnership Report

How can we engage women in Poplar and ex-offenders in an accessible training and employment programme that will address the critical shortage of technically skilled staff within the London fashion manufacturing industry?

Claire Swift

Jessamine Tierney

Alice Burkitt

November 2018

Image Decription: The exterior of Poplar Works on a bright, sunny day. Someone is riding their bike and a few people walk by. The building is black, white and red and the near end is an interesting geometric shape.

Acknowledgements

Image Description: A close up of some hands stitching with orange coloured thread on patterned fabric.

Project partners

London College of Fashion, University of the Arts London

University of the Arts London

United Kingdom Fashion and Textiles Association

Poplar HARCA

Stitches in Time

Newham College

Executive Summary

Poplar Works (previously ‘Fashioning Poplar’) is a £5.5m project, part funded by the Greater London Authority (GLA), led by Poplar HARCA together with London College of Fashion, UAL and workspace provider The Trampery. It will provide a distinctive space in the heart of the Poplar community, aiming to nurture undiscovered talent and potential and create new possibilities for future generations.

This new building, scheduled to open in Autumn 2019, will transform over 100 disused garage spaces into a unique Fashion and Makery Hub, comprising a garment manufacturing unit, low-cost design studios and “makery” workspace units

for business start-ups, education and training facilities, as well as a public cafe and events space. The hub will be built on a site within the Poplar Riverside Housing Zone, projected to deliver over 10,000 homes, and on the doorstep of East Bank and the Queen Elizabeth Olympic Park heralding the arrival of London College of Fashion, UAL’s new campus in 2022. Poplar Works will create an ecosystem of workspace, enterprise development and skills opportunities, with training and enterprise programmes being delivered by Trampery Pathways and LCF’s ‘Making for Change’ programme, as well as East Works: Fashion being delivered by the London Legacy Development Corporation at East Bank.

Poplar Works is a key part of the Fashion District, a new hub for London’s fashion industry aiming to return world-leading fashion manufacturing and design to east London with sites in East Bank, Queen Elizabeth Olympic Park, Hackney Wick, Haringey and Poplar. The Fashion District unites industry, business, education and the public sector in addressing the key barriers to growth for the fashion industry. This new hub aims to boost growth through thousands of new jobs, improving skills and training, and the provision of new affordable workspaces.

‘Making for Change’ will be a vibrant, community-focused fashion training and manufacturing unit based at Poplar Works.

Within this, there will be accredited training provision, employment opportunities and enterprise support programmes, predominantly for women from marginalised community groups as well as for a small number of female ex-offenders. It will also be a hub for students and alumni, local enterprises and ‘Making for Change’ participants to interact, engage, explore and collaborate on original and exciting project opportunities.

‘Making for Change’ at Poplar Works, will build upon the success of a University of the Arts, London College of Fashion (LCF) initiative that was established in partnership with the Ministry of Justice in 2014; a Fashion Training and Manufacture unit that is currently situated within a women’s prison at Her Majesty’s Prison (HMP) Downview, Surrey.

This consultation enabled partners representing education, the fashion and textile industry, charity and the local community to co-create a proposal for an accessible programme at the ‘Making for Change’ unit at Poplar Works. Throughout 2018 the partnership has undertaken consultations with both London-based fashion and textile industry and sewing communities within the local area of Poplar, in order to understand how to bring the talent and skills found within the local community together with the needs of the manufacturing industry.

This piece of work and the resulting activity at ‘Making for Change’ Poplar Works has the potential to have a wider influence. A successful pilot and the learnings from it can be used as a model elsewhere in London and the UK to bring new candidates into manufacturing jobs in the fashion and textiles industry. The community-based findings can inform the work of the Fashion District as it looks at ways of working with the population in east London . It also begins to address

the benefit of considering a new model of high-quality technical education, as set out in the ‘Building our Industrial Strategy’ Green Paper (January 2017) and the Mayor of London’s ‘Skills for Londoners Strategy’ (June 2018).

Consultation Overview

The Poplar Works Community Partnership consultation brings together partners’ specialist experience and knowledge to create an ongoing forum that will inform the design of an accessible programme at ‘Making for Change’ Poplar Works.

The partners within this consultation represented and explored the needs and requirements of primary stakeholders: local women and ex-offenders seeking training and employment, and the London fashion and textiles manufacturing industry.

The consultation focussed on:

• The needs of the fashion and textiles manufacturing industry coping with the demise of technical knowledge and manufacturing skills

• The existing skills and talent found within the community, and the issues that may be a barrier to engaging with a training and employment programme.

The aim of the consultation was to identify the key findings which will outline a series of recommendations, in order to inform a pipeline of skills suitable for the manufacturing industry, whilst simultaneously supporting the needs of the community participants.

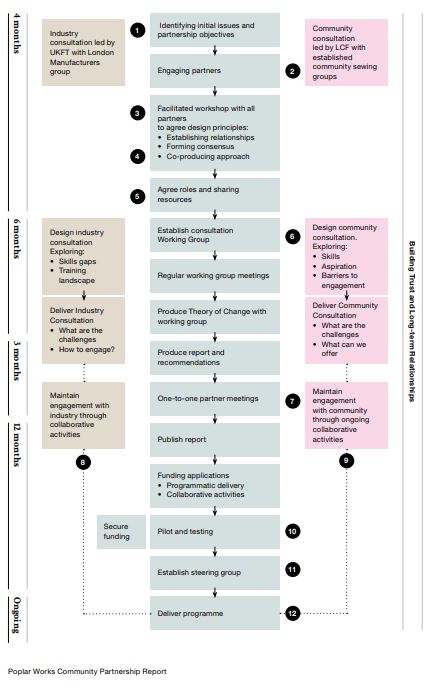

Partnership Process Map

London College of Fashion began establishing relationships with industry, education and community partners two years in advance of this consultation in order to establish resilient, long-standing partnerships that could increase the impact of Making for Change at Poplar Works on the local economy. It became clear that partners should work together more intensively to design a programme that responds to the significant skills gap within the manufacturing industry, whilst simultaneously supporting the needs of community participants.

Learnings / Context

1. We found it necessary to have a lead partner (LCF) to coordinate the partnership and drive the project forward

2. It was vital to have representatives from industry, education and community to represent a range of views and expertise

3. Funding was required at this stage to deliver a facilitated workshop, delivered by NEF Consulting who we engaged to support the monitoring and evaluation of the partnership

4. We tried to design a Theory of Change at this stage but found it was too early in the project

5. Funding was required at this stage to take the consultation forward

6. We began drawing up a Collaboration Agreement between all parties – a lengthy process

7. Meeting one to one with each partner at this stage enabled open conversations about next steps

8. For example, industry visits to Making for Change project, factory visits for community groups

9. For example, further fashion and textiles activities with community sewing groups

10. Delivering a pilot training programme offsite before Poplar Works opens enables us to test programme and maintain engagement

11. The project steering group should have a wider membership than the working group, to include programme participants, local businesses, students etc.

12. Programme delivery will begin onsite at Poplar Works

Key Findings

Local Community and Ex-offenders

Participants identified a strong connection to the ‘organisation’ as a positive feature of their local area

• Additional guidance and support services were cited as an important aspect to engagement.

• Language support – and ESOL classes build confidence in accessing other opportunities

A talent pool of both hand-sewing and manufacturing skills exists in the local community

• There is strong evidence of existing skills developed through on-going projects within the community

• Some participants have progressed to become teachers within their sewing community

There is a strong appetite for learning new skills and knowledge alongside a keen interest in learning and exploring new technologies

• The skills and confidence developed through long-standing sewing groups have produced an engaged group of learners who wish to progress their skills and knowledge to more advanced levels

• An introduction to industry technology ignited an interest to explore this further

There is a strong interest in self-employment and starting fashion based enterprises in the local community and participants leaving the HMP Downview project

• Self-employment and running an enterprise are seen by a significant number of people we spoke to as an attractive alternative to traditional employment

• Many people we spoke to enquired about space or equipment hire at Poplar Works, and advice and support in starting up an enterprise

There is a range of knowledge and educational qualifications which pre-exist in the community

• The range of qualifications and skills that need to be assessed, acknowledged and defined as a basis for further development

There is a keen interest in training and/or part-time employment

• A large number of participants are keen, enthusiastic and interested in training opportunities especially if they lead to employment.

• Some participants are restricted to part-time hours, defined by having school age children

Local participants wish to remain in the local area for training and employment

• The distance to travel to a place of employment was of a concern to many participants

• Again, participants with school age children need to be able to travel to and from work quickly

• Cost of travel is considered to be a restrictive factor

Issues regarding childcare and childcare costs were of concern to some participants who wished to engage with further training or employment opportunities

• The high costs of childcare are a restrictive factor regarding employment

• The benefits of earning may be negated by the cost of childcare

There is a lack of clarity about how training and work can affect benefits entitlement

• The complex and changing nature of benefits mean that people need and want to work but are concerned about being sanctioned or worse off if they access training or low-paid work

• Clear advice and guidance is required on an individual basis

People are keen to engage with the wider Poplar Works site and its facilities

• There is interest in involvement in the social spaces and other activities at Poplar Works including the café and garden and family workshops

• Social space and and quiet spaces are seen as important elements to include in the building to enhance user wellbeing

Participants of ‘Making for Change’ at HMP Downview regard Poplar Works as a valuable space to help them transition from the prison environment back into society

• Women who took part in the focus group stated that Poplar Works could offer a supportive and consistent environment for them to train or work in during Release on Temporary Licence (ROTL) and after release from prison.

• Women we spoke to would be happy to travel across London to access this opportunity

There is an engaged community of staff, students and alumni at LCF who wish to collaborate with the community in Poplar

• The successful involvement of staff, students and alumni in the consultation process evidenced the range and scope of opportunities for student and staff bodies and the local community to collaborate at Poplar Works

London Manufacturers

Previous delivery mechanisms not fit for purpose

• Funding structures favouring Apprenticeships have allowed little flexibility to explore other forms of vocational training

• Some ‘college-led’ models have been inflexible/not considered sector nuances

• Manufacturers nervous of the impact of on-the-job training element of apprenticeships on small teams

Entry Level training is required

• There is a need for participants to enter the workplace with a good basic level of skills

• Industry engagement in candidate assessment processes will help to develop an appropriate pipeline

There is a need to challenge perceptions that have become barriers to an uptake of training

• There is a poor perception of the manufacturing environment amongst career advisors

• There is a need to communicate a positive story about the environment and the opportunities available within the fashion manufacturing sector

• There is a need to create clear resources to explain the jobs available within the industry and make them accessible to candidates of all ages and backgrounds

Recruitment methods need revising

• Previously restrictive funding landscape is now becoming more flexible

• It is important to involve the industry at each stage of the recruitment process

Not enough industry engagement in the

development process

• Industry engagement is required in the design of all vocational elements of a training programme

Recommendations

Networks

Knowledge, skills, support services and employment opportunities already exist in and around Poplar, but further development is required to grow networks that connect people, enterprises and services together, in order to create a thriving fashion ecosystem in the community. The key recommendations that have arisen through this consultation are based on building knowledge exchange networks that can bring these currently disparate groups together.

Steering group

We will continue to meet all partners who have collaborated on the Poplar Works Community Partnership project, and will grow this group into a steering group that includes representatives from the local community, the local manufacturing

industry, wider fashion industry, sewing groups, social enterprise, students and Making for Change participants. This group will meet on a regular basis to co-design the programme at ‘Making for Change’ Poplar Works and beyond. This steering group will be in place by September 2019.

Support and progression

Local services exist to support people with the barriers they face to accessing training and employment. However the local landscape is complex and confusing for many to access. We can harness the knowledge and experience that the Poplar Works Community Partnership partners who are already rooted in the local community (Poplar HARCA and Stitches in Time) can offer to connect people to the support they need with housing, childcare provision, benefits and advice. A role is required at ‘Making for Change’ Poplar Works that can access and liaise with local services and provide tailored information, advice and guidance to participants, and the group will explore funding options for this integral position.

Sewing Groups

LCF, Stitches in Time and Newham College will work together, and with local sewing groups and training providers to design an offer at ‘Making for Change’ Poplar Works which complements and strengthens the existing programmes in the community, building a network of providers who can refer people to the right training offer or group at the right time.

Employability and Enterprise

In order to respond to the diverse range of skills, experience and living situations within the local community, the flexible training programme must accommodate different entry and exit points. This opportunity will offer employability skills specific to the sector, and the experience of different working environments before moving into permanent employment. In collaboration with the project and industry partners, we will design and deliver an additional programme of employability skills specific to the London manufacturing sector that can be delivered in addition to the fashion and textiles qualifications.

Additionally, we recognise that many local people want to develop their own fashion enterprises, work on a freelance basis or become self-employed rather than taking a more traditional route into employment. To address this local demand

LCF, Poplar HARCA and The Trampery will ensure multiple entry points are available in order to access fashion enterprise knowledge, and networks through lectures, events and workspace on offer within the wider Poplar Works project.

The handcraft skills that clearly exist in the local community are in high demand by London designers. We will create a local skills directory for London-based designers requiring high quality handcraft work to access the skills in the community, linking the talent pool in the community with the demand in the London fashion industry.

Stakeholder engagement

Strong relationships have been built with the local sewing community and manufacturing industry throughout this period of consultation, and will continue to be developed over the next year and beyond in the form of pilot programmes and other engagement opportunities.

Community Engagement

LCF, Stitches in Time, Poplar HARCA and Newham College will explore shared funding opportunites and deliver collaborative projects in the immediate and long-term future to deliver a pilot programme and other engagement activities locally. This will ensure continued engagement with ‘Making for Change’ Poplar Works and build a depth of understanding in the community of training and employment opportunities in the local fashion industry.

UKFT is developing promotional presentations, videos and other communications to demystify career routes in the fashion industry, and will develop further collateral about accessing the training scheme at ‘Making for Change’ Poplar Works.

LCF and Poplar HARCA will build on the positive relationship with Job Centre Plus to maximise local knowledge and referrals into ‘Making for Change’ Poplar Works or other local training opportunities. Through this relationship LCF will produce clear information on how training and employment through ‘Making for Change’ Poplar Works could affect benefits and finances.

LCF will work with HMP Downview to design a process that will best support the transition between engaging with ‘Making for Change’ HMP Downview and ‘Making for Change’ Poplar Works.

We will ensure LCF staff and student engagement is built into the delivery model, encouraging collaboration with the Poplar community, as well as start-up businesses at Poplar Works to support the co-creation of creative ideas and enterprise.

Industry Engagement

UKFT will galvanise the support of local manufacturing employers engaged in this consultation to create a pilot industry group that will become actively involved in designing and approving aspects of the Making for Change programme at

Poplar Works, including recruitment, employability and work experience programmes. We will work with employers who are open to adopting the Good Work Standard currently being developed by the Mayor of London to promote exemplary

practices in pay and employment rights for workers.

UKFT will continue to provide an industry liaison role within ‘Making for Change’ Poplar Works that can connect the programme with the manufacturing industry and support the development of specialist employability skills support for

participants.

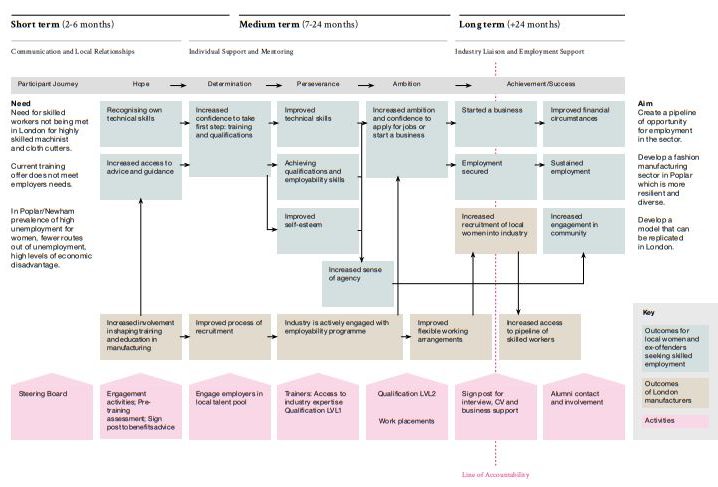

Theory of Change

This Theory of Change model was created with the representatives from all partner organisations, and defines the participant journey within an industry-informed context, illustrating a continually evolving process of change for both stakeholder groups.

Our Theory of Change identifies engagement activities that lead towards recruitment and training opportunities. This industry-led programme provides real work experience, building the technical knowledge and skills of the participants which

will help them to build their self-confidence, by achieving qualifications and improving their employability skills.

Feedback from participants of ‘Making for Change’ HMP Downview has helped us to shape this Theory of Change by understanding the participant journey through training and into employment. One woman described her experience as “giving me hope, that I can do this, I can get through this and become a better person”. Whilst acknowledging the challenges of their learning journey, the women have expressed that the experience provided them with the determination and perseverance necessary to progress and strive towards their goals. Another participant stated “It’s made me more confident in myself and my abilities and I don’t doubt myself in what I can do, I know I am more than capable.”

This Theory of Change builds on the stories of the women in prison as they measure their success by their skills and academic achievements, thus increasing their ambition, giving them the confidence to apply for and secure jobs, as they continue to utilise the skills learnt on the training programme.

The model has been created by combining the existing knowledge of the Making for Change skills programme with findings from the community enquiry and consultation. It proposes the pro-active engagement of the industry stakeholders at all stages from recruitment through to interviewing, work placements and employment. Consideration of the needs of the community and ex-offender participants is built in to the programme through flexible working arrangements, mentoring and employability support. This model aims towards cultivating a successful programme that will increase a local talent pool of skilled workers and develop a model that can be replicated in other areas.

The Theory of Change is a live and collaborative document that will continually evolve as the project progresses.

Governance

The project was coordinated by London College of Fashion, UAL, in collaboration with partner organisations responsible for project governance and delivery. Partners were invited to become part of the project for the knowledge and expertise they could offer in their field.

The project partners (see Appendix 1) comprised representatives from:

London College of Fashion, University of the Arts London Representatives:

Claire Swift, Director of Social Responsibility

Jessamine Tierney, Special Projects Manager, Social Responsibility

University of the Arts London Representative:

Angela Drisdale-Gordon, Head of Further Education

Stitches in Time Representatives:

Katie Adkins, Director of Enterprise and Outreach

Paul Garayo, Director of Projects and Partnerships

Kelly Shaw, Designer, Mini Stitches

Poplar HARCA Representatives:

Babu Bhattacherjee, Director of Communities and Neighbourhoods

Tanzeem Ahmed, Partnerships and Performance Manager (Communities and Neighbourhoods team)

Alex Jeremy, Head of Partnerships, ACCENTS

Newham College Representatives:

Julia Bollam, Director of Centre for Innovation and Partnerships

Gillian Jones, Head of School, Fashion and Tailoring

United Kingdom Fashion and Textiles Association (UKFT) Representative:

Alice Burkitt, Consultant for UKFT and lead of UKFT London Manufacturers network

In November 2017 partner organisations met to discuss the project, to agree on shared partnership objectives and activities and to begin to develop the proposed model of engagement. This meeting was facilitated by New Economics Foundation Consulting (NEFC) and proposed developing a Theory of Change approach that could be applied as a living document that progresses with the project.

Partners met on a monthly basis a further six times between January and June 2018, to monitor project progress and contribute knowledge and experience to the development of the partnership work.

“As a charity partner in this cross-sector relationship, the benefits were clear. We are well-positioned to represent and engage with the beneficiaries of the Poplar Works project, and to work at a strategic level with such varying and accomplished partners whilst developing a relevant person-centred approach has been incredibly valuable. Such partnerships work at their best over the long term, and the initial period of consultation has given the required time to interact with beneficiary groups, as well as develop the innovative groundwork for a successful long-term initiative. This means that going forward we will be able to ensure successful local engagement, activities that truly meet and adapt to rapidly changing landscape of social need, and importantly contribute to a practical research model that will form a sound basis for analysis as well as potentially becoming a national model for responsible and community-led enterprise.”

Paul Garayo, Director of Projects and Partnerships, Stitches in Time

Objectives

Objectives were agreed with all partners at the start of the project. Partners all agreed these objectives aligned with their own organisational objectives.

• Design an effective and participatory research methodology which will include designing a Theory of Change

• Deliver a series of consultation workshops and meetings with the local community to research local skills and represent local needs

• Work with London manufacturers’ representative (UKFT) to produce a series of recommendations on the workforce skills gaps and training needs

• Design an accessible and innovative model of technical curriculum delivery

• Outline a sustainable model that builds partnerships to impact long-term economic growth and regeneration

Knowledge Exchange

The partnership also enabled London College of Fashion to put in process considerable groundwork that is in direct relationship with the following UAL Knowledge Exchange objectives and will influence this project’s evolving long-term significance:

Attracting prospective students and enhancing our students’ learning experience.

• By co-designing (with partners and stakeholders) a flexible learning programme tailored to local demographic needs, it opens progression pathways and educational opportunities within this programme.

• A range of entry points will be identified, which consider English language and employment skills training to compliment the practical training.

Improving our profile and reinforcing UAL’s reputation as a place of educational and creative excellence.

• The development of a new approach to technical fashion education will offer solutions to the challenges found in both the fashion industry and disadvantaged communities.

• Designing a skills pipeline which combines community engagement and learning could create a model that can be replicated by other communities on a larger scale.

Generating income and developing relationships with businesses, industry, academia and the community to achieve positive social and cultural change.

• ‘Making for Change’ Poplar Works presents an opportunity to create a new social enterprise within the community that offers new approaches to traditional garment manufacturing.

• On-site opportunities at Poplar Works with designers, makers and new businesses, could include commissions, connections, sharing of skills and learning

• There is scope to build on the Making for Change social enterprise based in HMP Downview which is building a steadily increasing client base, and attracting ethical and sustainable emerging designers. (See Appendix 6)

Creating new knowledge by applying research to real life issues and increasing public understanding of the value of creative education.

• Through a new approach that involves collaboration with a diverse network of partners, this work begins to address a new method of technical education (as stated in the ‘Building our Industrial Strategy’ Green Paper (January 2017) and the Mayor of London’s ‘Skills for Londoners Strategy’ (June 2018).

• The learning within this project has great potential to facilitate positive change for the communities of the area and has the potential to influence the wider area through the work of the Fashion District.

Context

Local Landscape

The 2016 Labour Market Profile for Tower Hamlets indicates that 12% of females in Tower Hamlets are unemployed, in comparison to 4.7% of females in Great Britain as a whole. Despite recent improvements, Tower Hamlets is the third most deprived borough in London, with the highest percentage of children and older people living in income deprived households in the UK.

In the Understanding Skills and Qualification Levels in Tower Hamlets report published in June 2014 by London Borough of Tower Hamlets, residents with no formal qualification were shown to have by far the lowest employment rate of all residents, at only 30%. This rate was also the lowest in the country for this group. However, residents with a Level 2 qualification, (the intended level to train people within the programme at ‘Making for Change’,) were twice as likely to be employed, showing a clear positive link between qualification attainment and economic activity.

There is a particular prevalence of female unemployment in Tower Hamlets. To address these high levels of female worklessness in the borough, in 2011 Tower Hamlets Council launched their Employment Strategy, which was informed by specially commissioned qualitative analysis (‘Life Chances, Life Choices’ Naila Kabeer and Peroline Ainsworth, 2011) to better understand the reasons for high levels of economic inactivity among women. The resulting report examined the lives of 35 women from the Bangladeshi community and 29 from the Somali community, both communities with high levels of female worklessness in Tower Hamlets.

The report’s findings concluded that in the case of each community, a combination of historical and cultural factors perpetuated female unemployment. Culturally specific attitudes to early marriage, family rearing, and non-engagement with higher education have helped to perpetuate unemployment among these communities and many women often lack the skills and qualifications to enter the labour market. More broadly, it found that there was a fear that employment would jeopardise state benefits.

The Royal Society for the Encouragement of Arts, Manufacturers and Commerce (RSA) have long championed the importance of building community inclusivity into new urban developments. Their 2015 report ‘Community Capital; The Value of Connected Communities’, edited by Matthew Parsfield, recognises that building communities and supporting social relationships ‘produces measurable social value: greater wellbeing and empowerment, enhanced opportunities for employment and training, and the potential for savings in public service expenditure’.

Reflecting this, an independent evaluation of ‘Making for Change’ at HMP Downview, undertaken by Bath Spa University through consultation with the participants and completed in 2018, found that by taking part in the project, women experience improvements in mental health and wellbeing, social skills and confidence and future aspirations.

Industry context

East London has a rich history of clothing and textile manufacturing. However, decline in UK manufacturing over recent decades has meant that skills and knowledge learnt over generations have gradually been lost. Nevertheless, there is a wealth of skills and enthusiasm for fashion and textiles in Poplar, with many local women participating in community sewing and fashion projects. Despite this, there remain significant barriers to accessing formal training.

This project intends to address these barriers, re-invigorate the local economy, provide skills and opportunities and re-introduce technical skills and manufacturing jobs to a new generation of east London communities.

London holds a high concentration of fashion manufacturers in a small geographical area. These businesses deliver high quality services to the fashion industry from the high end to the high street, they have abilities across product and are typically micro SME in size. There is a clear and steady increase in the demand for the ability to manufacture in the UK (not least in London) and therefore an increasing need to support their growth potential.

As an illustration:

• In 2016 there were an estimated 13,500 manufacturing employees in London according to the Office for National Statistics (ONS)

• In 2017 the Alliance Project Report estimated that the Industry (across the UK) would require an additional 20,000 manufacturing employees in the next five years

One of the most crucial issues to address in order to support growth is the critical shortage of technically skilled staff. In order to meet the increased demand (anecdotally estimated up to a 20% increase) these businesses will need to significantly grow their workforce. Currently there is no latent talent pool or domestic pipeline delivering staff with the appropriate skills.

As many manufacturing roles are currently filled by staff from across Europe, with some manufacturers actively recruiting in countries like Romania and Poland, the result of the vote to leave the European Union has threatened a significant current supply. There is a need to address the retention and protection of the existing skilled workforce but most crucially there is a critical need to deliver new methods of domestic recruitment and training specifically for this part of the industry.

UKFT is supporting the members of its London Manufacturers group to collectively find a solution and has been working with the Poplar Works Community Partnership to develop a mechanism to trial at ‘Making for Change’ Poplar Works.

Creating a mechanism to deliver skilled people into manufacturing roles will:

• Allow these businesses to keep up with the demand for quality London/UK based manufacturing

• Create employment in areas of typically low employment and suitable for those furthest from the workplace

• Contribute to the London and UK economy

“There is evidence of strong manufacturing growth in the Upper Lea Valley; despite its structural challenges, manufacturing is the fastest growing fashion sub-sector, with a 94% increase in employment and 128% increase in GVA between 2010 and 2015.”

The East London Fashion Cluster, Strategy and Action Plan, BOP Consulting 2017

UKFT’s 2016 survey of a representative sample of London based manufacturers highlighted the following:

• All businesses surveyed predicted a growth in their staff numbers between 2016 and 201

• All businesses surveyed reported they employ at least one EU citizen (not including British)

• Over 87% of those surveyed revealed they currently suffer with a shortage of skilled staff

• 86% of businesses surveyed revealed the struggle to recruit sewing machinists

• 75% of businesses surveyed revealed the struggle to recruit cloth cutters

• Pattern Cutter featured frequently within other roles businesses said they struggled to recruit

Using this information and subsequent industry consultation as evidence, UKFT advises the Poplar Works Community Partnership to focus on the roles of Sewing Machinist, Cloth Cutter and Pattern Cutter.

“There is evidence of strong manufacturing growth in the Upper Lea Valley; despite its structural challenges, manufacturing is the fastest growing fashion sub-sector, with a 94% increase in employment and 128% increase in GVA between 2010 and 2015.”

Community Consultation

The following are the occupation profiles for these roles as defined by industry for the purpose of training development:

Sewing Machinist (Appendix 2)

Sewing Machinists are responsible for stitching together fabric pattern pieces to make garments. They use many different types of sewing machines, including computerised equipment.

The Sewing Machinists role is fundamental to the production process right across this diverse, multi sector industry.

Image Description: Somebody sews at a white sewing machine, their face is not visible behind the machine.

Cloth (Materials) Cutter (Appendix 3)

For any sewn product before sewing can begin, pattern pieces must be made, layouts determined, and fabric cut. Following the outline of the pattern, they place multiple layers of material on the cutting table and use an electric knife or

other cutting tools to cut out the various pieces of the garment; delicate materials may be cut by hand.

In more automated facilities, markers electronically send the layout to a computer-controlled cutting machine, and textile cutting machine setters, operators, and tenders monitor the machine’s work.

Pattern Cutter (Appendix 4)

The role of a pattern cutter involves interpreting a product design brief and drafting patterns that reflect the design and technical specifications. Pattern cutters act as a link between the design and manufacturing stages, translating the 2D sketch into the 3D plan for the garment. This plan is called a pattern, and it is what is used to cut the cloth in the correct shapes in order to make up the garment.

It is important to note that these are the industry wide definition of these roles. London based manufacturers predominantly operate as CMT (cut, make, trim) facilities with an increasing number of sampling units and a handful of fully

factored production units. They typically handle small production volumes and high value products and materials.

For the role of sewing machinist this requires a higher skill level including more hand sewing skills and finishing techniques. Sample machinist is also a role that is in high demand in London. Sample machinist would be a role to progress onto after industrial sewing machinist. This role is required both in-house within design studios and within manufacturers that develop patterns and samples (see accompanying progression route documents for detail).

For the role of cloth cutter within this environment manual skills are important and the understanding and ability to handle ‘difficult’ fabrics is required.

The role of pattern cutter is required both in-house within design studios and within manufacturing units who develop patterns and samples. Within London it is likely that both the construction and the fabrication will be complex, so a high skill level is required.

In all areas a high skill level is required but speed and productivity is still important.

Over a period of six months, London College of Fashion, UAL, in collaboration with project partners, facilitated a discourse with community groups, their leaders, teachers and participants, gaining an understanding of participant involvement with the sewing groups and aspects of life within the local community. In order to tailor a programme of activity at “Poplar Works” it has to consider and respond to local issues and needs.

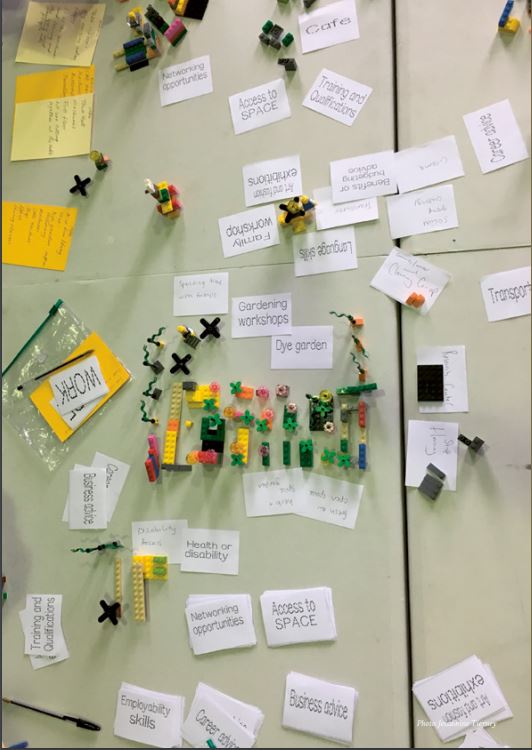

The consultation was structured to learn about existing skills and ambitions, whilst trying to understand the potential barriers which may affect participants’ ability to engage with regular educational classes or employment. A range of methods were used to create a dialogue with the community groups; from questionnaires, to visual cards, and Lego serious play, which facilitated the sharing of ideas, alongside simple making activities.

LCF also consulted with female offenders and ex-offenders in the form of a focus group. ‘Making for Change’ Poplar Works can provide important employability opportunities for female offenders who have successfully completed their placements and are ready to become more actively involved in the ‘Making for Change’ Poplar Works project upon release.

Participant groups were selected according to their proximity to “Poplar Works” and their current or previous sewing activities. In this way we were able to work with people likely to access “Poplar Works” in the future, and who could reflect on their relevant experience and skills in fashion and textiles.

Participant Groups (see Appendix 5)

• Stitches in Time advanced group

• Stitches in Time English with Sewing group

• Aberfeldy Centre group

• Bow Sewing Enterprise Group at the Linc Centre

Methodology and Activities

Primary stakeholders:

• Local unemployed women in Poplar (particularly those already engaged in sewing groups)

• Participants of London College of Fashion’s training and manufacturing unit at HMP Downview

Through the consultation we aimed to work with the primary stakeholders to identify:

• Existing sewing skill levels and experience

• Employment skills and experience

• Short and long term goals relating to wellbeing and employment

• What opportunities they would like to see offered at Poplar Works

• Barriers to sustained engagement in education and employment

• How best to engage effectively and collaboratively with the local community

• The possibility of establishing a group of potential future participants / trainees and steering group members at Poplar Works

The consultation was broadly split into three themes:

Skills, Aspirations and Barriers. We were also keen to explore how participants feel about the regeneration in the local area, which Poplar Works is part of.

Workshops

In February 2018 LCF met with NEF Consulting to devise the consultation workshop delivery methods and data collection, based on the project aims and objectives. The workshop delivery was further designed in collaboration with facilitator and LCF MA Fashion Futures alumni Jessica Ball.

It was decided that it would be most beneficial to work with four local sewing groups, over two half-day sessions each, in order to start building meaningful relationships with the community. Each group was given an opportunity to take part in both a creative workshop at their own community centre and also a visit LCF’s Mare Street site.

The workshops were designed to be informal and interactive so that we could share information with the local community and vice versa.

Workshops activities included:

• Sharing information on Poplar Works and the opportunities to get involved

• Sharing information on the fashion industry and different career paths within it

• A ‘making’ activity – hand sewing and embroidering a small bag

• A natural dye workshop delivered by LCF PhD student Katelyn Toth-Fejel

• Interactive activities to encourage conversation and opinions – Lego Serious Play, drawing and conversational activities

Mare Street visits include:

• Tour of workshops and an explanation how they are used (including tailoring, jewellery, art workshops, contour etc.)

• Watching short films on careers in the fashion industry, that were created as part of the Poplar Works Community Partnership project, featuring LCF staff members who also work in industry

• Introduction to dye garden

• Interactive and reflective activities

Information was collected through:

• Registration, consent and detailed feedback forms

• Photographs

• Interactive and reflective activities

• Informal conversations during making activities

• Appropriate consent forms also to be designed to take part in workshops and use data

Findings

A visual presentation of the proposed site for the Poplar Works was given to all groups at the beginning of their first workshop, informing the participants of the partners involved in the project, the community garden, café and exhibition space as well as proposed educational and business activities.

• 68 participants took part in at least one workshop or visit

• 59 participants completed questionnaires during or after workshops

• 52 participants who completed questionnaires stated that they had little or no knowledge of Poplar Works prior to taking part in a workshop.

• It was encouraging to learn that after the workshop activities 53 participants felt more informed and had a greater knowledge of the project.

• When asked whether Poplar Works would support positive change in the area, 35 of the participants agreed and 19 strongly agreed, evidencing an optimistic response to the project.

General demographic

The LCF facilitators were able to communicate with and gain information from a total number of 59 participants included in the four groups.

Of the total number of participants that completed questionnaires, there were 56 women and 3 men, 22 of the participants are within the 36-45 age group, and 14 are in the 46-55 age group. There were 45 participants who defined their ethnicity as Asian/British Bangladeshi.

Skills

Image Description: a close up of a pair of hands holding a piece of blue and pink patterned fabric with a floral design stitched in the centre.

Image Description: A workshop table with paper, fabrics, thread and other sewing items.

The learning of skills in a regular, organised, activity (Robertson & Vinebaum, 2016) brings people together in a physical space which encourages dialogue, exchange of knowledge and builds a community (Gauntlett, 2011) and social interaction. In this way, the groups that LCF were able to consult with, were deeply connected to their community, defined by the sewing and craft skills that they were learning in the safety of a ‘family’ workshop environment that (Sennett, 2008) provides ‘a place that unites family and labour’. Participation in local sewing groups may often be less about the individual and more about building a community of shared interest and facilitating social connections. The findings in the workshop activities evidenced that 7 of participants were using their skills as a hobby rather than displaying ambitions for employment or training, whilst 19 of the participants stated that connection to the ‘organisation’ (the sewing groups) was an important aspect of their local area. The Stitches in Time groups particularly talked about the ‘community’ of the Town Hall and access to other services and organisations as an important part of the wider support and involvement in the group.

All of the participants were asked to rate their sewing skills levels; 16 self-reported ‘excellent’ skills, 18 assessed their sewing as ‘very good’, and 15 considered their skills level to be ‘good’. This response indicates a large number of participants reporting a high-level of confidence in their skills and abilities. When asked ‘what they would like to learn more of’ 21 participants wanted to learn more advanced sewing machine skills, 4 participants are interested in pattern-cutting whilst

3 participants are interested in learning basic design knowledge.

Many of the participants were particularly interested in learning more about the types of industrial machinery and technology that they had been shown at the London College of Fashion site visit and cited the range of machinery as a point of interest and enthusiasm when asked ‘what they would like to see at the Poplar Works site’. A range of different statement cards were used in the workshops and the ‘learning new skills and knowledge’ card was used frequently by the participants when expressing what they would like to access at Poplar Works, or when asked about their future ambitions.

“It is an equal and fair community, with lots of individuals and personalities.” SiT participant

“This centre is good and interesting, I enjoy meeting and speaking with lots of different people.” SiT participant

Stitches in Time

“Since coming to classes I am most proud of being able to write my name and address also saying it confidently. Through speaking with my teachers I have overcome some family problems. If I hadn’t joined the classes, I would have suffered at home.

I heard about classes from a friend. Since coming, I have improved my English, and I am very proud of being able to do some voluntary work and making friends. I want to be able to speak good English. Before joining, I wasn’t happy, I was stressed at home now I feel happy I know I have got somewhere to go. Since coming to class I am very happy, it has changed my life. I know I can share my problems and get help. I want to do more volunteering.

My friend told me about the class at the Museum of Childhood, then I joined the sewing class at Limehouse Town Hall. My spoken English has improved so much I am really proud of myself. I want to further improve my English and hope to get a job. Before I joined Stitches in Time I used to get lonely and depressed. Since joining I have made so many friends. Stitches in Time has helped me through my hardest time. I went through some personal problems they helped me all the way. Even out of hours I could contact them. I have volunteered on the doll stall at the Mela and the museum. I received direct experience working with the public. I really enjoyed myself. I would still be in a big problem at home. I would be very depressed.”

Statement from Stitches in Time participant, 2018

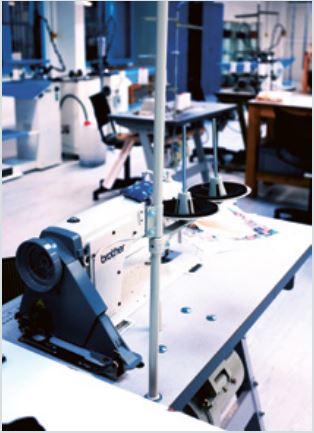

Image Description: A white workshop with sewing machines on tables

Wellbeing

Atkinson (2014) Robertson & Vinebaum (2016) and Collier (2011) propose the therapeutic qualities of making and the connection to wellbeing. Historically, sewing and craft was a tradition executed by women in the communities, associated

with home textiles and the making of clothing as a gender focused activity. Atkinson (2014) however, cites that although the manufacturing industry is struggling to recruit skilled and accomplished workers, the quality and skills found within the industry may prove to be beneficial to the health and wellbeing of workers.

The Prison Reform Trust Bromley Briefings Prison Factfile (2016) reports that women in prison represent 21% of incidents relating to self-harm, and 49% suffer with anxiety and depression, compared to 15% of the normal UK population.

Dr. Laura Caulfield (2018) evidences that women who have participated in the Training and Manufacture Programme in HMP Downview have spoken positively about improvements in their wellbeing. The women learn manufacturing skills in a supportive learning environment and they have acknowledged the impact of learning these skills on their mental health.

Handcraft skills

One of the workshop engagement activities was to hand sew a small drawstring bag and to design a hand-embroidered embellishment on the front. This bag making activity provided an insight into the existing embroidery skills of the participants. The facilitator was demonstrating a simple blanket stitch to the women as a means to finish the edge of the bags. This stitch was unfamiliar to the participants, therefore took a little longer to learn. However, most of the women were using similar, complex embroidery stitches as embellishments on the front of their bags in a range of different abstract and floral patterns. The women stated that these were traditional stitches that had been taught in childhood, used on many traditional products and textiles. The women executed these stitches to a high quality, with ease and self-confidence. The women stated anecdotally, that these embroidery skills were a part of their cultural traditions and had not considered using these specialist skills either through the development of an enterprise or as a means of freelance activity working with local designers.

“I’m not on the antidepressant, because when I come to work it’s not even being in prison, I’m in a working environment, yeah, being productive, feeling that self-worth as well, having my confidence back.”

Participant 2, Making for Change HMP Downview

Aspirations

Qualifications

The questionnaire enquired about the types of qualifications achieved by the participants, measured against the standard UK qualifications, however, this did not identify the breadth, range and level of qualifications achieved by the participants. A few of the participants indicated examples of the type of qualifications achieved in Bangladesh: Tailoring courses, Business Management and Political Science, and other UK courses; Diploma in Nursing and ESOL language courses. This would necessitate further enquiry, as 31 of the participants indicated they had achieved qualifications as ‘other’ than those UK standard qualifications as identified in the questionnaire. In understanding the nature and level of these ‘other’ qualifications, this would help to diagnose and facilitate a pre-entry assessment.

Participants were asked about their future plans, and their interest in further training and employment. Some of the participants indicated that caring responsibilities, and unemployment benefits, are factors that contribute towards an uncertainty regarding full-time or part-time commitments.

In regards to current employment status, 23 participants were unemployed and receiving benefits, whilst a further 10 were unemployed and receiving no benefits, indicating that some

participants are supported by their working partners (many of the women in the ice-breaker session talked about their caring responsibilities for their children and the occupations of their husbands, chef, taxi-driver etc. which supported the family) 6 participants were already in part-time employment.

When asked if the participants would be interested in a training course: 34 participants said yes, however, 27 participants emphasised they would not wish to train full-time.

There were 32 participants who stated they would be interested in part-time employment, 19 would be interested in working part-time in a fashion-related business and 9 participants would like to run their own business.

My Dream Job

This consultation evidences positive aspirations and ambitions within the community. Many of which have been supported through the long-standing work of the existing community sewing groups, especially regarding the provision of training,

language support and the positive social community interaction of the participants. Stitches in Time have loyal, engaged and enthusiastic participants who, have remained active with the group over a number of years as they progress from learner to trainer, evidencing how a fully supportive programme can benefit the participants.

“I would like to be a theatre costumer designer and making production and working with people in theatre.”

Poplar Sewing Group participant

“I would like to have my own business making shalwar kameez and employ people to help me.”

Poplar Sewing Group participant

Barriers

It is important to discuss the barriers that many of the community participants may experience, which includes many of the women who leave prison, who may have little or no access to financial support, the stability of a family environment or

prospects of employment.

Standard of Living

“A minimum standard of living (MIS) in the UK today includes, more than just food, clothes and shelter. It is about having what you need in order to have the opportunities and choices necessary to participate in society.”

(commissioned by Trust for London, authored by Researchers from the Centre for Research in Social Policy, Loughborough University)

The Minimum Income Standard Report (MIS) (2016-17) identified that issues faced by families living in London, make it far more difficult for families to reach a ‘socially accepted’ standard of living in London (Trust for London, MIS standard report). Over 41% of Londoners live below the normal standard of living, in comparison to 30% across the UK.

The main issues which Londoners experience are high housing costs, childcare and travel and are the most significant factors faced by people living and working in London. London households pay up to 40% higher rent than the national average.

Additionally, public transport costs for Londoners are more than twice that that experienced by the rest of the UK. When questioned “how far they would travel to work”, 25 stated the furthest distance would be one bus ride away from home, 32 preferred a travel time of between 10-30mins, which indicates a preference to remain within the local area.

Through the workshop activities and questionnaires participants were asked what support they would need to access training or employment in the future. Childcare costs, assistance finding childcare, advice about benefits and flexible hours were the most frequently cited issues raised. The MIS reports that families in London are expected to pay at least 31% – 41% more than the UK average childcare costs.

Overall, the minimum cost of living is about 20% more for a family in London than outside London. Even in social housing, parents in London require earnings of at least £28,000 a year each to reach a minimum standard. (Trust for London, MIS standard report)

Benefits system

The benefits landscape is changing rapidly at a national and local level, with the phased introduction of Universal Credit starting in 2017. Poplar was one of the first five areas in the country where the new system was introduced, meaning that

new claimants with fewer than three children could apply for Universal Credit. The government intends to begin transferring existing benefits and tax credits claimants to universal credit from 2019, with a target that all people claiming benefits or tax credits will be moved to Universal Credit by 2023. However, complications in its delivery and ongoing political debate about this new system could well affect this timeline.

It was identified throughout the consultation through conversations with local people and organisations that there is widespread confusion and fear surrounding eligibility for benefits and how undertaking work or training could adversely affect household income. This prevents many local women from engaging in formal training and employment, although many of them want to.

The partnership researched the local landscape through communication with Job Centre Plus contacts, with the intention that a flexible model of training and employment could be offered at Poplar Works, with clear guidelines to be produced and shared with potential applicants on how engaging with training or work at Poplar Works could affect their benefits and financial situation. This proved more difficult than expected due to the current complex landscape of different benefits and the changing landscape which means that there are numerous different situations that individuals could find themselves in.

HMP Downview Focus Group

In June 2018, LCF delivered a 3-hour focus group with four women, all of whom have experience of taking part in London College of Fashion’s ‘Making for Change’ project at HMP Downview. One woman is currently undertaking a Release on Temporary License (ROTL) placement at London College of Fashion, one woman is a current member of the Making for Change project, nearing release who was given permission to attend for the day, and two women were previously participants on the project, who have since been released from prison.

The Poplar Works project was presented to the women, who were then asked a series of questions regarding:

• Their experience of the training programme at Making for Change at HMP Downview

• For those who have been released, their experience of being released and their views on how Poplar Works could be best designed to support women into work and training on release from prison

• Their views and suggestions for opportunities and programmes at Poplar Works

All the women were overwhelmingly positive about the intention for a site based in London where they could continue their training or be employed.

All the women agreed that:

• They wanted to continue to pursue fashion either as a hobby or a career

• They were interested in setting up their own businesses but needed support

• They wanted to continue the connection with London College of Fashion, whether through training or employment

• They would be happy to travel across London to access Poplar Works if they had the funds to do so

• They thought the opportunity should be offered to all Making for Change participants on release from HMP Downview

“Just staying in touch, the transition from that environment (Downview) to this environment (LCF) (is important). When I say ‘I’m going to do this today with London College of Fashion’ it’s a good feeling”

Participant in HMP Downview focus group

“When you come out of prison you need to integrate yourself back into society so having these two groups coming together (community and ex-offenders) is a nice way to do that”

Participant in HMP Downview focus group

Other key points raised in the discussion included:

• The need for a quiet space and social spaces onsite at Poplar Works

• The women were keen to think of ideas to help support and fundraise for ‘Making for Change’ at Poplar Works through ideas such as an onsite fabric store or pop-up shop

• Childcare duties could be a barrier to engaging in training or work opportunities if they are not flexible

• “When you’ve got kids it’s finding that time to do what you want to do…I’m scared that if I go to work here or there will I make it back on time to pick up my kids”

Participant in HMP Downview focus group

In the discussion about the experience of being released from prison, and what could help ex-offenders to progress into training and employment, it was stated that:

• On release from prison, ex-offenders are given £46, but little support to locate housing or work, or how to claim benefits, so without a support network it is very difficult to focus on anything other than these urgent issues

• Lack of funds to cover travel costs and childcare costs could potentially deter them from accessing training or employment

• Some women were set up with mentors to meet with regularly on release but the mentors weren’t usually able to offer practical advice, which is what they felt they needed the most

It was suggested that:

• A supportive exit strategy should be set up for each participant over the 6 months before release, to provide tailored advice and guidance to each individual

• ‘Making for Change’ participants could benefit from being provided with information on relevant support services, organisations and funding that they could access on release, in relation to both continuing their sewing skills and basic needs

• ‘Making for Change’ participants could be provided with a ‘kit’ with sewing equipment, an oyster card and other useful items on release, to help them to continue to sew at home and to travel to appointments

• It would be beneficial to access mentors or staff members who could offer practical advice before and after release

London Manufacturing Consultation

Training and Delivery Issues

It is important to understand the complexities affecting the execution of a successful training solution in London, from an industry perspective i.e. not excluding, but not focusing on, the social/community barriers.

There have been several historic attempts to develop a mechanism to bring new skilled staff into manufacturing jobs in London, however, so far, none have succeeded in delivering a fit-for-purpose scheme to satisfy demand. UKFT know this

from regular informal engagement with industry and from our recent formal consultations. In short there is still a wide spread and severe skills shortage for the roles of sewing machinist, cloth cutter and pattern cutter.

There are multiple complex reasons for this.

A changing landscape

Since the Richard Review of Apprenticeships (see Appendix for detail) in 2012 there has been an ongoing period of change within the training landscape for all sectors.

Although Apprenticeships are not the only answer, this is where the national (government led) focus has been and, therefore, where the majority of funding for training has been directed.

Following the Richard Review, government has continued to ask industries to take greater ownership of their skills agendas. The main result of which has been a total review of all Apprenticeship Frameworks (due to expire by 2020) and a coordinated migration onto Apprenticeship Standards, a process which UKFT has been at the heart of in a coordination and secretariat capacity.

Alongside the changes to the schemes of learning there has also been a change to the way Apprenticeships are funded, all Apprenticeship training is now funded through the Levy system (see Appendix for more detail.)

For the fashion and textiles sector there was additional change as the former Sector Skills Council handed the responsibility of skills and training in the sector to UKFT, now the government appointed Sector Skills Body.

Whilst in the main these changes have been positive, there has been a resultant ‘hiatus in training’ in the sector until the landscape became more settled. This has occurred at a time where, as previously discussed, the need to recruit and train new skilled staff into a flourishing manufacturing sector has become increasingly critical.

The industry has now reached a more settled position from which to build some valuable training programs, whether Apprenticeship based or not.

Funding inaccessible

The previous funding mechanism for Apprenticeships was hard to use for much of the fashion and textiles industry, particularly those based in London. Government would fund 100% of training costs for 16 to 18-year olds, 50% of the costs for those aged 19 to 24 and offered no funding support for training over 24’s (except a 24+ learner loan). There were a number of reasons why this did not work for the London based manufacturers:

• Manufacturers predominantly look for candidates with a strong desire to be in and stay in this environment and therefore commonly look to recruit those in their late 20s or above

• Learner loans were not considered an option for those looking at this type of work and training

• Paying the remaining 50% of the training costs was unachievable for the majority of businesses, all which are SME, many micro SME. For some apprenticeships this would have been as much as £6,000 per candidate, therefore businesses could not recruit 19 – 24-year olds.

• Most manufacturers reported that they did not want to recruit a 16 – 18 year old, those that did consider 16 – 18 year olds found that volumes of applications were extremely low (even with the support of training providers) and the rare candidate that was found was often not comfortable in the environment or with the role.

Delivery mechanisms not fit for purpose

With the previous funding for training favouring apprenticeships there has been little flexibility to explore other forms of vocational training. Previously trialed/offered apprenticeship programmes have had low or no uptake from London Manufacturers.

A significant barrier to apprenticeship uptake has been the inflexibility of some ‘college led’ models. In some cases, the nuances of the sector were often not factored in and therefore the training was hard to use. In these cases those manufacturers who did explore apprenticeships described the feeling of trying to fit a round peg into a square hole and in the main found recruitment processes were not able to deliver appropriate candidates.

Many manufacturers were ‘nervous’ of the on-the-job training element of the apprenticeship, fearing their valuable staff would be ‘off their own job’ whilst training a ‘brand new’ candidate – having a significant impact of the productivity of small teams resulting in financial strain.

Critical Mass

One of the common barriers to delivering successful training in the UK fashion and textiles industry is achieving the critical mass regionally to make delivery economically viable and attractive to training providers. 90% of the UK fashion and textiles is SME and often individual companies only have the need for one or two candidates, so clustering/coordinating need is essential.

UKFT is working with their London Manufacturers group to ensure that the businesses in need of new staff are involved in its development and that the training delivered will meet the real needs of the industry. By engaging this group in the development process it will be easier to demonstrate a critical mass and a commitment to train and employ.

Entry level training required

Whilst there are currently training schemes offering valuable delivery to other parts of the fashion industry in London the needs of the high-end fashion sector are specific and nuanced and so require a new, specific, industry owned delivery mechanism.

High end manufacturers work with high value products and materials in an environment where there is little margin for error. Candidates are required to enter the workplace with a good basic level of skill but for these businesses qualifications and apprenticeships are not the only answer.

A sustainable, industry designed and recognised entry level training programme with industry approved tuition is needed. From this an appropriately skilled talent pool can be generated from which manufacturers can recruit into jobs or further on-the-job training.

The good news is that the qualification on which to base this training does now exist. A lack of entry level training was for a long while identified by fashion and textiles businesses across the UK as a national market failure. In response, and in order to prepare new entrants for industry roles before entering the workplace, the ABC Level 1 Award in Fashion and Textiles was developed. There are currently twelve frameworks available at this level for F&T but the ABC level 1 award is the only one going through the UKFT Industry Recognition Programme (IRP).

The aim is for this to be delivered in a live or simulated manufacturing workplace to give new entrants the opportunity to ‘taste’ the requirements and environments of a manufacturer. Candidates finish with a nationally accredited, industry recognised, qualification that offers multiple pathway options into multiple job roles in the sector. Potential employers are able to understand the candidates’ level of competency before entering the workplace. They can also be confident that they have the aptitude and drive to pursue a manufacturing job, ensuring a greater success rate for further on-the-job training or employment.

A number of ‘stitching schools’ have optimised the programme nationally with a notably high success rate for completion and progression into further education, apprenticeships or full-time employment.

However, an industry fit method for implementing this to suit the specific requirements of the London manufacturing sector still needs to be developed.

Pipeline issues

In London, and across the UK fashion and textiles industry, there are numerous challenges that are affecting the delivery of industry fit training and talent pipelines. In 2017 UKFT were asked by the Department for Education (DfE) to feed into a number of consultations requiring industry input. The response included the following concerns:

• There is a severe shortage of Fashion & Textiles provision in pre-16 learning (e.g. GCSE in Design and Technology: Textiles Technology)

• The industry feel very strongly that through this lack of provision and accurate sector information the fashion & textiles industry miss out on a talent pipeline

• These concerns lead back into early school-based learning where there is also a lack of creative provision that will severely impact the talent pipeline

The need to change perceptions

In London, and across the UK, there is a need to challenge some existing perceptions that have become barriers to uptake of training.

• Many employers have previously tried using Apprenticeships to expand their workforce and have experienced many of the issues identified above. There is now a need to communicate the new look Apprenticeship standards, funding and delivery and to myth-bust some of the negative perceptions.

• There is a poor perception of the manufacturing environment amongst career advisors, young people and their parents. There is a need for a sector wide campaign to communicate the environment and the opportunities available within the fashion manufacturing sector.

• There is a need to create clear resources to explain the jobs available within the industry and how to access them. These resources must be accessible to candidates of all ages and backgrounds.

Recruitment methods not fit for purpose

Previously recruitment into training has been led by funding restrictions and often by training providers. It has commonly been the most significant barrier to the uptake in apprenticeships for London manufacturers.

As discussed, now the funding restrictions have been lifted it is possible to target more suitable candidates to train.

With the UKFT London Manufacturers group in place it is now possible to promote opportunities in the sector en masse rather than business by business. It is also important to have the employers at the heart of this process so that they receive candidates that will thrive in their work place and remain employed.

Not enough industry engagement in the development process

In the Fashion and Textiles sector there have been a number of successful training models that we can learn from. Each of these models have been targeted, needs driven and business led and have consequently successfully overcome near crippling skills shortages.

These models have all demonstrated clear industry ownership of their schemes, developed an exciting promotion of opportunities and strong recruitment pathways. However, these examples have all used apprenticeships to find a workable solution. Whilst this is a method that has worked for some groups of businesses our evidence demonstrates this is not the only solution for the London manufacturers.

One of the key purposes of the UKFT London Manufacturers group is for these businesses to come together to develop a training and recruitment solution for them and by them.

Training Programme: Industry Criteria

As previously discussed the London Manufacturing sector is in a period of growth and needs to develop a new pipeline of skilled people entering into manufacturing jobs in order to utilise opportunities. UKFT have been working on behalf of

their London Manufacturers group to develop an outline of the needs and considerations that must be taken into account when developing a training solution for these businesses. The following is a summary of both formal and informal consultation with representative business in the sector.

Develop a mechanism that generates an approved talent pool from which manufacturers can recruit pre-trained candidates with an appropriate level of skill and productivity onto jobs or further on-the-job training. The program must

focus on delivering candidates into highly skilled cutting, machining and finishing jobs, as well as addressing roles such as pattern cutting and pressing.

The recruitment of candidates into pre-training programmes must be industry led. The recruitment process must consider the employment requirements of the manufacturers and where possible potential employers must be

involved at this stage.

UKFT will be creating a recruitment brief on behalf of the group and will help to facilitate a talent pool and recruitment process.

The mechanism must be flexible to allow candidates of differing abilities to enter and exit the pre-training programme at different points that suit them and their would-be employer. In some cases, it may be that manufacturers will refer a potential employee to the programme. Some candidates will have prior experience but manufacturers would like them to go through a recognised training programme before employing them.

In addition, the needs of London manufacturers are varied, particularly in terms of product type, therefore the model, funding and delivery must be flexible.

An industry approved assessment process must be developed that will assess candidates at the start and the end of their training. This will ensure they receive the correct level of training whilst on the programme and that they are ‘ready for the work place’ when they complete. This assessment will need to take into account not just technical ability but any wrap around support or training they may require – this could include employability skills, English language training, financial support, circumstantial needs and any other ongoing support they will need in order to successfully become a longterm employee.

Should there be candidates who do not show the correct aptitude for the role they are training for, they must be offered opportunities to use what they have learned to train into other roles in this environment, for example, pressing.

UKFT will be creating an industry approved candidate assessment process on behalf of the group.

A period of work placement must be included in the pre-training programme – this may be multiple placements. This will allow the candidates the chance to understand the manufacturing environment, the context of the roles within it and the variety of products and materials manufacturers in London work with. It will give them the chance to understand where their aptitudes lie and where they would most like to work. It will also give manufacturers the chance to

get to know would-be employees and how they will fit within their business before they employ them.

The recruitment of candidates into the work place must also be industry led. Employers must be involved in the final assessment process and interview stage at which point jobs and further on-the-job training will be offered.

This part of the programme must also be flexible to accommodate different employer and learner routes. ‘Further on-the-job training’ may be in the format of apprenticeships but if the learner and employer wish this can also be informal training whilst employed.